Labs & Facilities

Centre of Excellence for Digital Manufacturing and Automation

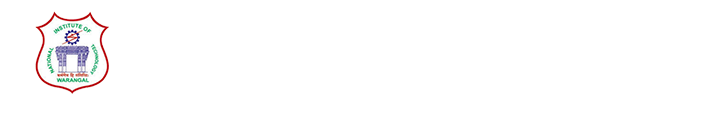

- Siemens NX CAD 1980

- Solid Edge 2021

- Fibersims 17.1.1

- Mastertrim 15.1.1

- Syncrofit 15

- Fe Map 2021.2

Lab Overview:

Based on technology from Siemens, this Lab focuses on Product Digitization. Moreover the facilities in Lab provides the most powerful, flexible and innovative product development solutions in the industry through NX software. Supporting every aspect of product development, from concept design through engineering and manufacturing solutions. The NX for Design has multiple tools to benefit user in 2D & 3D CAD Modelling, Design Interoperability, Mechanical - Electrical/Electronic Design, Design Validation, Design for Manufacturing, Molded Part Validation & Injection Molding Simulation, Industrial Design & Styling, Reverse Engineering, Mechatronic Concept Design, P&ID Design, 3D Electrical Wiring and Harness Design, Aero Structures Design, Automotive Design, Marine Design Solutions and many more.

- Technomatix

- Process Simulation

- Plant Simulation

Lab Overview:

Based on technology from Siemens, the lab focuses on Product Digitization. This Lab facilitates factory layout design and optimization through Tecnomatix software. Digital Twins Navigation, Virtual Commissioning of Automated Systems, Plant Simulation & Throughput Optimization, Human-Centered Design and Planning, Ergonomics & Human Performance, Offline Robotic Programming and automation, Press Line Design & Simulation, Impact of Dimensional variation, Work Instruction Delivery, Manufacturing Process Planning, Assembly Simulation for Virtual Process Verification, Production Logistics & Material Flow, Material Flow Optimization, Factory and Line Design are some of the modules available in the software.

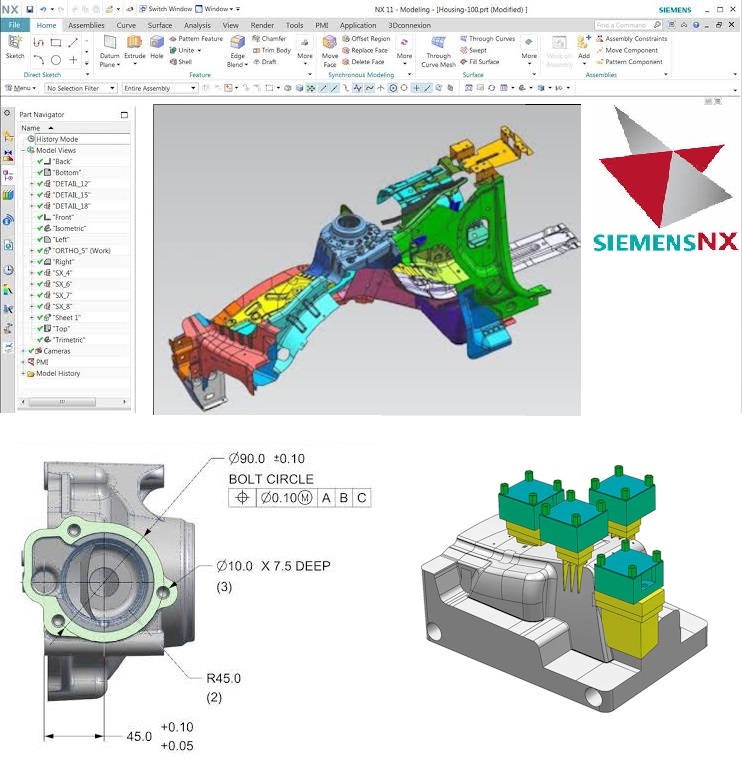

- Technology - MultiJet 3D Printing (MJP)

- Machine - 3D SYSTEMS Projet MJP 2500 Plus

- Post processing - MJP Easy Clean System (Bulk Wax Removal & Fine Wax Removal)

- Software- 3D Sprint

Lab Overview:

Colleges and universities with 3D printing technology can prepare students for a workforce that demands sharp critical thinking and collaboration skills. The right technology attracts not only bright students but also talented faculty and valuable industry partners, leading to valuable business partnerships that can give a vital real-world experience.

- SIEMENS MindConnect Nano

- SIEMENS Insights Hub (MindSphere - Cloud Software)

- Raspberry Pi, Arduino, NodeMCU, Beaglebone Black

- Texas Instruments - Launchpad, Development Board, Booster packs

Lab Overview:

Based on technology from Siemens, the Lab teaches Internet of Things (IoT).The Internet of Things, or IoT, is emerging as the next technology mega-trend, with repercussions across the business spectrum. By connecting to the Internet billions of everyday devices – ranging from fitness bracelets to industrial equipment – the IoT merges the physical and online worlds, opening up a host of new opportunities and challenges for companies, governments and consumers.

- MAPS 6S (Modular Automation Production System with 6 Stations) - 2 setups

- PLC-S7 1200

- TIA Portal V16- Ladder Diagram (Programming Language)

- PROFINET- Communication Protocols

- User Manuals

Lab Overview:

Based on technology from Siemens, the Lab teaches Automation (Mechatronics). Mechatronics is defined as a field that integrates multiple disciplines such as mechanical, electronics, control, instrumentation and programming, that enables operators, technicians, supervisors, managers and designers to design, optimize, operate and maintain real-world automation processes, that comprise of these multiple technologies. The Mechatronic lab brings together four departments of engineering, namely Mechanical, Electrical, Electronics & Communication and Computer Science. This allow Trainees to work on a mini factory-like setup and on areas such as Pneumatic s & Hydraulics, Sensors, Communication Protocol, PLC programming, PLC Networking using PROFIBUS and PROFINET.

- SIEMENS Sinu Train: Simulation for CNC Programming

- MTAB Max Mill Plus + CNC Vertical Machining Cente with SIEMENS 828D Controller: Automatic Tool Changer is capable of holding 20 tools

Lab Overview:

5 Axis Simultaneous operation VMC is one of its kind state-of-the-art machining center available at COE . It can be used for machining of parts with complex geometries, and profiles and having intricate manufacturing process sequence. The Trainees will be trained to operate industry-grade machines and develop complex parts for biomedical, automobile and other industries.

- KUKA Spot Welding Robot

- KUKA Arc Welding Robot

- Robot Controller (KUKA KRC4)

- KUKA KRL Programming

- HMI- KTP 700

Lab Overview:

Based on technology from KUKA, Robots play an important role in the manufacturing industry, ensuring that the quality of the product is not compromised and the production volumes met. The spot welding and arc welding robotic cells with KUKA SimPro software from KUKA will enable Trainees to understand kinematics, Cell creation, trajectory planning and motion planning of robots for specific welding tasks. Focused on Robot simulation and programming practices to surge career opportunities through industry-oriented training module.

- CNC Turning Machine (2 Axis)

- CNC Milling Machine (3 Axis

- DIR Articulated Robot + RTU (Robot Transfer Unit) – (6+1 Axis)

- SCARA Robot (4 Axis) with DRA Studio

- Siemens S7-1200,S7-1500 PLC with TIA Portal

- AGV (Automated Guided Vehicle) with AGV Studio

- KTP Basic HMI Device

- Manual Tapping

- Vision & RFID Inspection Station

Lab Overview:

Smart Factory Lab integrates Automation, CNC Machines, Robotics and other related fields. This lab enables the trainees to work on Various CNC Machines, both 4 & 6 Axis Robots using DRA Studio, Siemens PLC with TIA Portal, AGV etc. It brings Interoperability, Virtualization, Real-Time Capability and Modularity to Control the Entire Manufacturing Process. It integrates Process, Control, Data Exchange Automation, Inspection and Quality Control with RFID Technology, Material Handling etc. Our Automation System enables efficient Management, Monitoring and Implementation using diverse Control Technologies. It enables the trainees to make the Manufacturing Setup and Produce various good for the Factory.

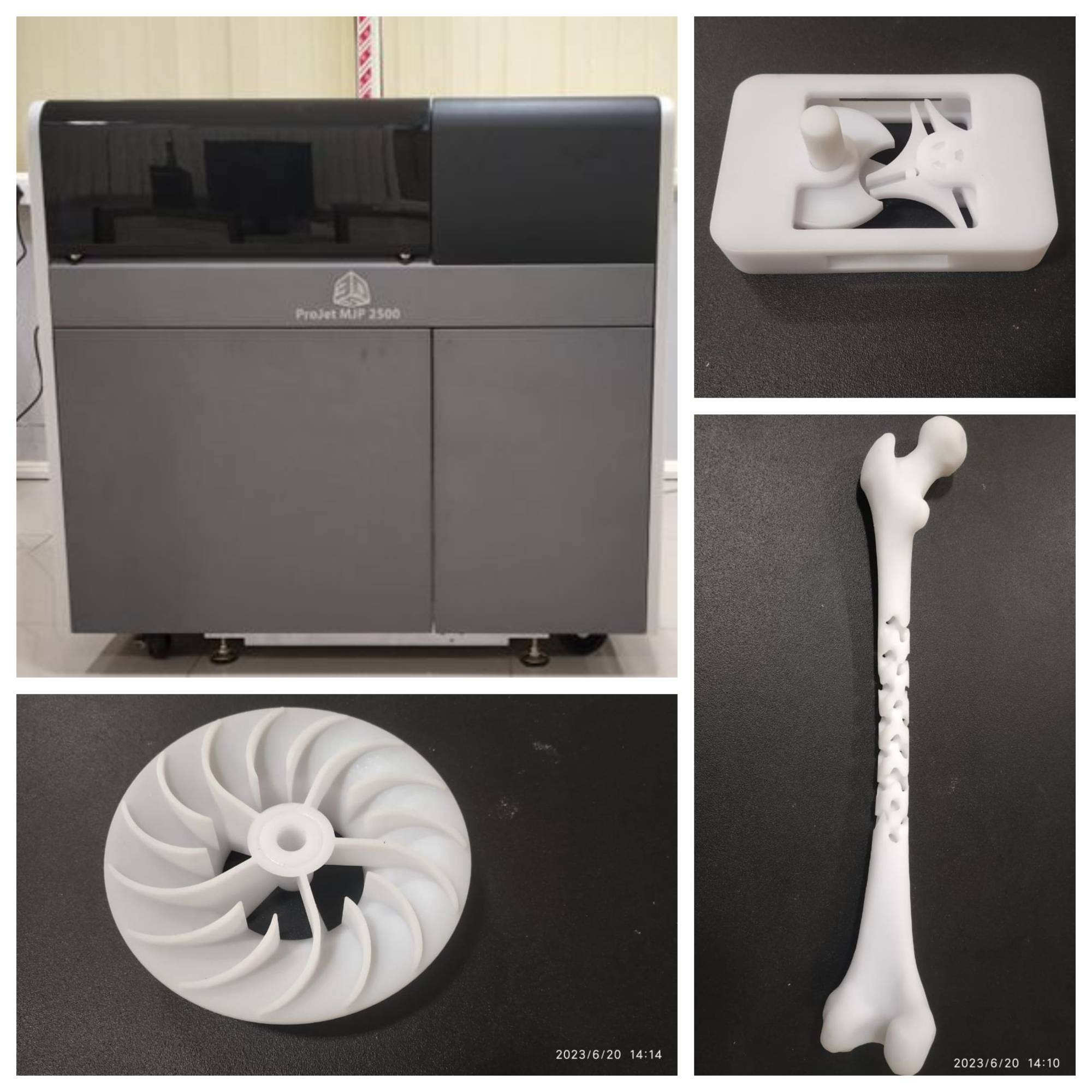

- PCS7 Training Kit with S7-400 CPU and ET200PA Distributed I/Os

- Sensing Instruments: Tempetature (RTD), Pressure, Level, and Flow measurement

- Control Instrument: Ball valve with Electro-Pneumatic Positioner (SIPART PS2)

- HART and Profibus USB Communicator

- Simatic Manager v9.0 for ES, AS and OS Programming

- WinCC Explorer and WinCC Runtime for SCADA

Lab Overview:

Based on technology from Siemens, the goal is to provide students and professionals with the knowledge and skills they need to work in the field of process instrumentation.

The Process Instrumentation Lab enables Trainees to work on Distributed Control Systems (DCS) using Process Control System (PCS 7) and understanding the working of the following

equipment’s in a plant: Temperature, Flow Level Pressure Sensors/Measurements; communication. PI lab leads to connecting computerized systems with Instrumentation

helps to set long-term Goal in the automation sector using SIMATIC PCS 7. SIMATIC PCS 7 furnishes more scalability, availability, and security in process automation. It

makes your plant fit for the future with more security, proactive lifecycle management, and innovative plant engineering.

For More Information, Click below.

Lab Tour Process Instrumentation PCS7 WinCC

- SIEMENS Sinu Train- Licenses 840D Sl4.8 SP4: Simulation for CNC Programming's, execution of tool paths and Workpiece in 3D modeling effects.

- SINUMERIK 808D & 840 Milling Training controller kits: To execute Tool Paths & Simulations.

Lab Overview:

CNC Machine and CNC Controllers play key role in the manufacturing industries to deliver quality products and parts in compliance with the customer demand and industry standards.

- Simcenter STAR-CCM+ for CFD analysis

- Simcenter 3D for Structural analysis

- Simcenter Testlab for data acquisition with testing and analytical tools

- Simcenter SCADAS Mobile hardware

- ICP Force sensors

- Scaled Airplane Model

- Accelerometer

Lab Overview:

Based on technology from Siemens, the Lab teaches Advanced Engineering Analysis (CAE). The Test and Optimization Lab addresses complex engineering challenges safeguarding the balance between technological design options and functional performance. From testing and mechanical simulation to model-based systems engineering it enables engineers to understand the functional performance engineering of mechatronic systems. it can solve issues related to noise, vibration and harshness (NVH), acoustics, durability, dynamics, performance, fuel economy and control development. The system simulation, 3D CAE and testing facility help trainees and industry to predict performance across all critical attributes before and during the entire product lifecycle. By combining physics-based simulations with insights gained from data analytics, Simcenter helps Trainees & industry optimize the design and deliver innovations faster.

- PLC S7-1200 & PLC S7-1500

- HMI KTP-700 & HMI TP-700

- SCADA - Simatic WINCC Professional (PC System)

- TIA Portal V16 - Ladder Diagram (Programming Language)

- PROFINET - Communication Protocols

Lab Overview:

Based on technology from Siemens, the Lab teaches Automation. Automation is the creation and application of technologies to produce and deliver goods and services with minimal human intervention. The implementation of automation technologies, techniques and processes improves the efficiency, reliability, and/or speed of many tasks that were previously performed by humans. The Automation Lab allows the trainees to understand the requirement and functioning of Programmable Logic Controllers (PLCs). This is the first step toward Internet of Things (IOT). Here the Trainees learn how to Program Industrial PLCs, work with Industrial Human Machine Interface (HMI), Industrial SCADA (Supervisory Control & Distributed Acquisition) and PLC networking using PROFIBUS and PROFINET.

- Energy-saving Kit

- 3WL & 3WT Air Circuit Breaker

- Timer and Relay Kit

- Soft-Starter

- G120 AC Drive

- 6RA80 DC Drive

- Simocode Pro

Lab Overview:

Energy efficient electrical systems have always been the priority for

industries across the verticals. The knowledge on high performance equipments,

high standard protective instruments and the best industry practices for

energy conservation. contribute significantly to facility management &

facility engineering.

This lab offers the opportunity to make in-depth study of the Industrial

equipments and explore energy efficient strategies

that can be deployed in the industries to deliver customized consulting and

market specific solutions.

The facilities : Advanced SINAMICS G120 for 3 AC 400V standards drives,

DC Drive-6RA80, demo case for L V industrial switchgear set.